Static afterburner portable Brinell hardness tester includes C-type Brinell hardness tester, hydraulic Brinell hardness tester and magnetic Brinell hardness tester. American Standard ASTM E110-2012 and China Metallurgical Industry Standard YB / T 4285-2012 "Test method for the determination of metal indentation hardness using a portable durometer" specifies the method for Brinell hardness test using these durometers. The drafting of the national metrological calibration specification JJF ×××× "portable Brinell hardness tester" provides a calibration method for these durometers.

C-type Brinell hardness tester

The main frame of C-type Brinell hardness was C-type structure. The instrument is used to apply a test force by means of a screw connected to the handwheel and a calibrated elastomer. The amount of deformation of the elastomer measured by an indicator can determine the magnitude of the test force.

The C-type Brinell hardness tester uses 613 N (62.5 kgf), 1226 N (125 kgf), 1839 N (187.5 kgf) test force, the diameter of carbide ball is 2.5 mm or 5 mm. According to GB / T 231.1-2009, the instrument indication error and repeatability error must meet the GB / T 231.2-2012 technical requirements.

According to the instrument size of the opening, C type Brinell hardness tester has models 2 '' ~ 20 ''. C-type Brinell hardness tester is easy to carry with small size and light weight. Its test methods and test accuracy is the same to desktop and in line with the corresponding national standards. Therefore, its test results are true and reliable.

C-type Brinell hardness tester is mainly used in the production site of the product sampling or carry out to do acceptance inspection.

Hydraulic Brinell hardness tester

The hydraulic Brinell hardness tester uses a hydraulic principle to produce a 29420 (3000 kgf) test force by manual operation. The core part of the durometer is a small hydraulic device with a spring relief valve for controlling the test force. A pressure gauge is used to indicate the size of the test force. When the test force reaches 29420 (3000 kgf), the release valve opens and the pressure drops. In accordance with the provisions of the US standard ASTM E110-14 to repeat the afterburner 3 to 4 times, so that the pressure gauge pointer reaches 29420 (3000 kgf) for 3 to 4 times. This equivalent to Brinell hardness test method on 29420 (3000 kgf) test force, diameter 10 mm ball head, afterburner 10 ~ 15s provisions. The indentation diameter is measured by an optical instrument, and then the obtain Brinell hardness value from the table. American Standard ASTM E110-14 and the Chinese metallurgical industry standard YB / T 4285-2012 provides Brinell hardness test method of the hydraulic Brinell hardness tester.

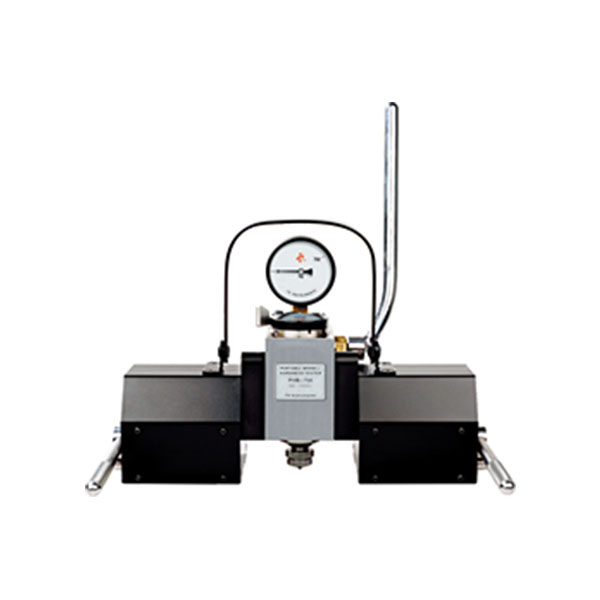

Hydraulic Brinell hardness tester can be used in three different ways to keep the ball head in contact with the specimen surface.

Method 1, the hydraulic device is installed on a lift bracket and it can clamp the workpiece with different thickness by adjusting the height of the hydraulic device. The structure is suitable for test the workpiece with two parallel surface.

Method 2, Fix the hydraulic device in the cylindrical workpiece by chain. The kind of structure is suitable for the test tube, shaft and other cylindrical workpiece.

Method 3, Adsorb the hydraulic device on a larger plane workpiece by two magnetic suction cups. The structure is suitable for testing die steel, thick steel plate and other steel parts with a larger plane.

The quality of Hydraulic Brinell hardness is 13.8 ~ 15.8 kg, the indication error and repeatability error are in line with GB / T 231.2-2012 technical requirements.

Hydraulic Brinell hardness can be carried with simple operation, high precision and reliable test results. Permanent Brinell indentation can accurately reflect the true hardness of the cast steel, cast iron, forgings and other coarse grain. The measured indentation can be used re-examination.

Hydraulic Brinell hardness is very suitable for the production site and large parts to do piece by piece hardness testing. The instrument is so far the largest domestic and international experimental Brinell hardness tester. It is also the preferred hardness testing equipment in international trade with very wide application. Daye Special Steel, Guangdong Fuhua and other enterprises have dozens of hydraulic Brinell hardness tester in the production site. The drawback of the kind of instrument is that it is easy to damage after frequent use with heavy equipment and high labor intensity.

Magnetic Brinell Hardness Tester

Magnetic Brinell hardness tester consists of two magnetic suction cups and a hardness measuring head. Fix the hardness tester on the surface of the steel workpiece by using magnetic attraction. The test will be completed as long as the hardness tester contact the workpiece. Magnetic hardness tester contains mechanical and digital.

(1) mechanical magnetic hardness Brinell hardness tester

The mechanical magnetic Brinell hardness tester is shown in Fig. 5, and its measuring head is similar to the C-type durometer. The test force is applied by means of a screw connected to the hand wheel and a calibrated elastomer. The amount of deformation of the elastomer measured by an indicating table to determine the magnitude of the test force.

(2) Electronic magnetic Brinell hardness tester

Electronic magnetic Brinell hardness tester shown in Figure 6, the probe has a microprocessor and force sensor. The instrument applies a test force through a screw connected to the handwheel, measures the magnitude of the test force by the force sensor, and the force value is displayed on the display.

Magnetic Brinell hardness tester uses 1839 N (187.5 kgf) test force, diameter 2.5 mm Carbide ball head, test method according to GB / T 231.1-2009 and YB / T 4285-2012, and the test accuracy is in line with GB / T231. 2-2012 technical requirements.

Magnetic Brinell hardness tester can be tested on a flat surface with a minimum measuring area of 180 mm (length) × 60 mm (width) and a thickness of 5 mm. The hardness tester can also be tested on a cylindrical surface with a minimum specimen diameter of 60 mm, length 200 mm and thickness 8 mm (pipe).

Compared with the mechanical magnetic Brinell hardness tester, the electronic magnetic Brinell hardness tester has higher precision and better stability. Brinell hardness test results is the same to desktop hardness tester. In addition, Brinell hardness test results can be corrected by standard Brinell hardness.

Magnetic Brinell hardness is very light with only 5 kg. Besides, it has the advantages of simple operation, rapid detection, high precision and high reliability. Its error can be corrected. This instrument is very suitable for detecting the large workpiece hardness on production site. As long as the workpiece has a place to absorb the instrument, the workpiece of any shape, any size can be tested.