Brinell hardness testing method was put forward by Swedish engineer J.A.Brinell from 1899 to 1900

when he studied the effect of heat treatment on the microstructure of rolled steel. This hardness

testing method is the earliest used hardness testing method, and it is still widely used up to now,

because the indentation obtained by Brinell hardness testing method is larger, its hardness value is

less affected by the uneven composition of the tested sample, the dispersion of the testing results is

small, and the reproducibility is good, which can well reflect the true hardness value of the material.

1. Brinell hardness testing principle and calculation formula

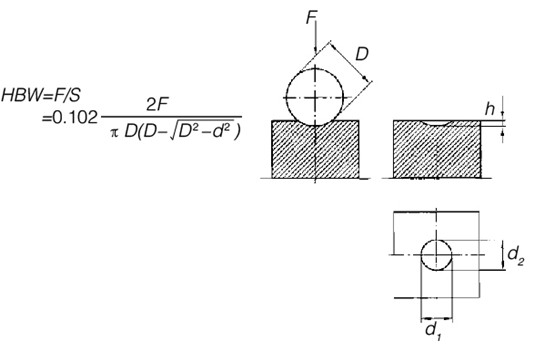

A cemented carbide ball with a certain diameter is pressed into the surface of the sample under

the specified test force F. After a certain test force holding time,the test force is removed, and the

indentation diameter D left on the sample surface is measured. The Brinell hardness is calculated

by the quotient of the test force divided by the indentation surface area S.

The calculation formula is as follows:

2. The application scope of Brinell hardness testing method

The pressure and indenter diameter used in Brinell hardness testing are large, and the indentation

diameter obtained is also large, which determines that this hardness testing method is suitable for

testing metal materials with large grains, such as castings, forgings, steel, tempering and annealing,

normalizing heat-treated parts, nonferrous metals and their alloys, etc. Especially for some soft

metals, such as aluminum, copper, lead, tin, zinc and their alloys. Brinell hardness testing method

also has its limitations in practical application. This testing method firstly applies a certain test force

to the tested sample, then uses a special optical instrument to read the indentation, and finally looks

up the table to get the Brinell hardness value. The testing process takes a long time and has many

steps. Besides, because the selection of test force and indenter diameter is large, the indentation

obtained is generally large, which is a destructive testing method.

3.Matters needing attention when using Brinell hardness testing method

1). In industrial production, the Brinell hardness value of workpieces shall be tested strictly in accordance with ASTM and ISO standards.

2). Generally, the ambient temperature during testing should be between 10℃ and 35℃.

3). For the selection of test force and indenter diameter in Brinell hardness testing, please choose according to the relevant provisions of ASTM and ISO.

4). Before the test, the surface of the sample should be smooth, free of oxides and other dirt.